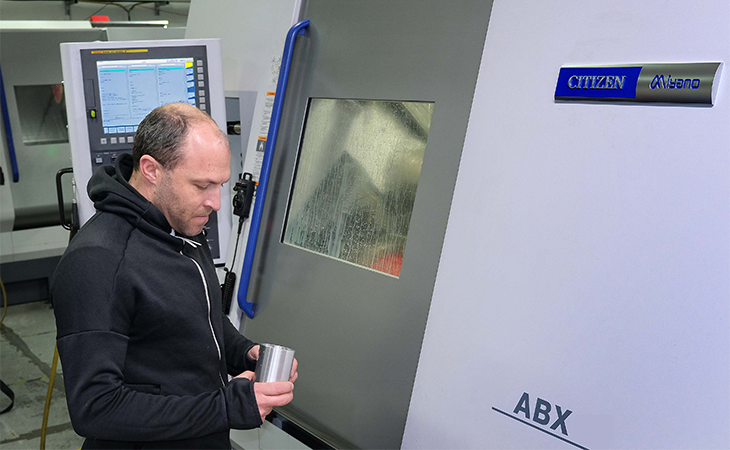

These days when turning and milling components less than 38 mm in diameter, it is difficult to justify using a fixed-headstock CNC lathe, such is the high level of capability, productivity and flexibility of modern sliding-head turning centres (sliders). This is the view of Martin Lock, owner of 55-years-established subcontract machining firm PES Engineering, Burnham-on-Crouch, who took delivery of a Cincom L32-XLFV slider from Citizen Machinery UK in April 2022.

He said, “We held off investing in this technology before, as up to about five years ago sliding-head lathes were not as flexible as their fixed-head counterparts in terms of their power or the number of tools in the working area. Consequently they could not produce such a wide variety of components, but that is no longer the case.

“Modern sliding-head lathes are able to produce anything a fixed-head equivalent can, and on average completes the same cycles in two-thirds of the time. It is down to the speed of movement of the gang tooling and the wealth of static and live cutters that can be deployed.”

Chipbreaking software is a game-changer

PES Engineering has over the years developed a reputation for supplying components in small to medium size batches, typically 3,000- to 5,000-off. Larger quantities are often produced and stocked at Burnham-on-Crouch for Kanban call-off by customers. Materials range from stainless steels, which account for half of throughput, to plastics, which make up another 20 percent. Both tend to generate stringy swarf when machined on the subcontractor’s fixed-head lathes.

PES Engineering has over the years developed a reputation for supplying components in small to medium size batches, typically 3,000- to 5,000-off. Larger quantities are often produced and stocked at Burnham-on-Crouch for Kanban call-off by customers. Materials range from stainless steels, which account for half of throughput, to plastics, which make up another 20 percent. Both tend to generate stringy swarf when machined on the subcontractor’s fixed-head lathes.

Swarf invariably wraps around the tool and the component being machined, risking damage and prematurely wearing the cutting edge of the carbide inserts. Feed rates have to be reduced to mitigate abrasion, lowering production output. Furthermore it is generally necessary to stop a lathe regularly to remove the swarf, making light-outs running virtually impossible unless a free-cutting material like brass is being processed. All of this negatively impacts productivity and profitability.

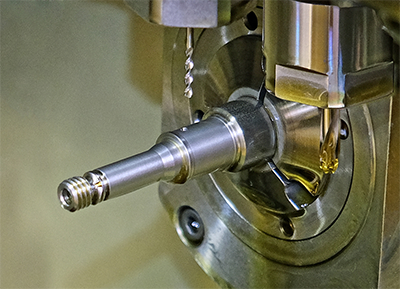

Such problems are not encountered on the Cincom slider, as it is equipped with Citizen’s programmable low frequency vibration (LFV) software in the operating system of the Mitsubishi control that breaks the swarf into smaller chips. Launched five years ago, the three modes of LFV developed to improve turning, grooving, drilling, boring, threading and parting-off not only avoid bird’s-nesting, but also reduce or eliminate the need to use expensive and energy-hungry high pressure coolant equipment.

Mr Lock continued, “LFV has removed much of the aggravation of turning stainless steels, which gives us a much easier life. We can machine efficiently everything from 304, which is billed as free-cutting but really is not, through to highly alloyed marine grades.

“With LFV, oscillation of the spindle relative to the axis feed motion momentarily and repeatedly lifts the tool clear of the component surface. It has the effect of breaking the swarf before it has a chance to form a string and also lowers the temperature at the point of cutting, reducing work hardening of the metal and preventing built-up edge on the insert.

“We have LFV switched on permanently when machining plastics and it works perfectly, even on nylon. When processing stainless steel, for nine out of 10 components we produce it is engaged for typically half of the cycle and always for parting-off. Programming the function to stop when it is not needed limits the milliseconds of slightly decreased metal removal rate when the tool is air cutting.”

Strategies that Mr Lock previously used to control swarf length included introducing peck feeding and dwells, which extended cycle times and accelerated tool wear, and experimenting with different chipbreaker designs on the insert. None of this is needed any more, as he says most materials chip like brass simply by selecting cutting parameters out of Citizen’s LFV manual.

Purchasing decision

At the end of last year, two 40 mm capacity fixed-head lathes producing 304 stainless steel medical parts broke down on the same afternoon, prompting Mr Lock to look for a replacement. As sliding-head technology had advanced sufficiently to consider it, he decided to go down this route. He was in regular contact with another subcontractor with which he occasionally shares work, and that company operates 10 Citizen lathes including LFV Cincoms that have proved to be reliable and accurate over the years. Once a machine is warmed up and set, tolerances do not move and machining to within microns is routine.

At the end of last year, two 40 mm capacity fixed-head lathes producing 304 stainless steel medical parts broke down on the same afternoon, prompting Mr Lock to look for a replacement. As sliding-head technology had advanced sufficiently to consider it, he decided to go down this route. He was in regular contact with another subcontractor with which he occasionally shares work, and that company operates 10 Citizen lathes including LFV Cincoms that have proved to be reliable and accurate over the years. Once a machine is warmed up and set, tolerances do not move and machining to within microns is routine.

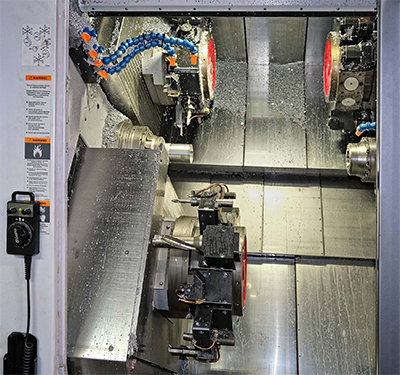

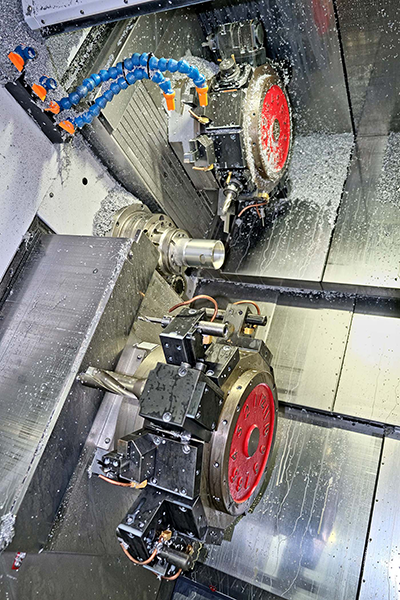

It therefore made sense for PES Engineering to opt for the Citizen brand. An L32-XLFV was duly ordered with a conversion kit that allows stock up to 38 mm in diameter to be fed from an Iemca three-metre bar magazine. Immediately apparent was the sheer speed of the machine, with many parts coming off more than twice as quickly compared with the output from one of the ageing fixed-head lathes. In one extreme case when turning a plastic part unattended, 400-off were produced in two hours instead of over a full manned shift.

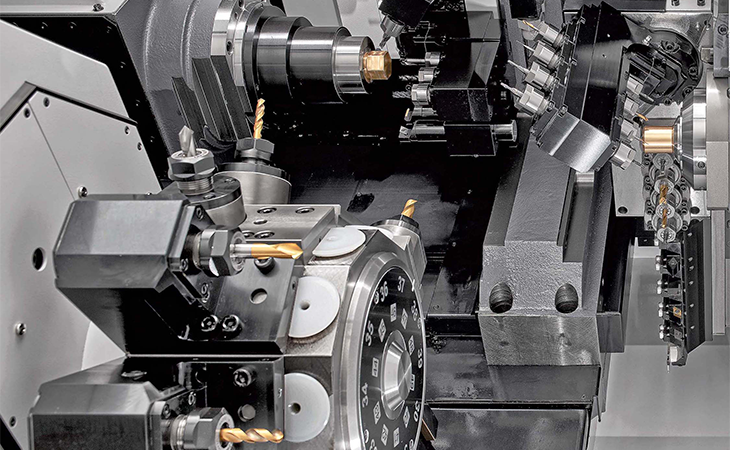

Two tools can be in cut simultaneously on the slider for high levels of productivity. Moreover the latest-generation L32-XLFV has a Y2 axis on the sub spindle, allowing cutting operations to be shared more evenly between it and the main spindle, minimising cycle times.

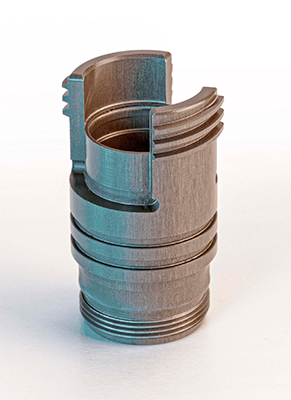

In the first three months of operation, the slider produced 20,000 parts of around three dozen varieties, all but one of which were in length less than 2.5 times the diameter. The majority were therefore not classical sliding-head work, so Mr Lock plans to take advantage of the ability on most Cincoms, including the L32, to remove the guide bush. The main advantages are the ability to use less expensive bar, as straightness and dimensional variation are not so much an issue, and a four-fold reduction in remnant length at the end of each bar, leading to significant material savings.

The Cincom is not only the first slider that Mr Lock has bought, but it also represents the first time he has dealt with Citizen Machinery UK. He has been impressed with the supplier’s service, which he describes as “refreshing”.

He added, “We have had fantastic human interaction and service from everybody in the company, from the sales team through ordering, machine installation and commissioning to service back-up.

“If we email or phone Citizen’s service department, we receive a call back in half an hour – sometimes within a couple of minutes – something other suppliers never seem to do in our experience.

“With the Cincom being our first slider, we were reliant on prompt and comprehensive telephone advice at the outset and still are to some extent. It has proved invaluable.”

About PES Engineering

Established in 1967 by Mr Lock’s father Clifford and a partner who subsequently left, PES Engineering derives its turnover from milling and turning in approximately equal measure. Industries served are mainly aerospace, automotive, medical, hydraulic, rail and electronic connectors, and customers are to be found throughout the UK as well as in the US and Germany.

A particular specialism is design for manufacture, i.e. redesigning components to simplify their manufacture and reduce the cost of production, while maintaining the part’s full functionality in service. In one recent case, an injection moulded plastic component that was proving difficult for a US customer to assemble with other parts was re-engineered so that it could be turned from plastic bar at an acceptable price. The result was highly satisfactory and the contract is ongoing.

In conclusion, Mr Lock observed, “Automating the turning side of our business using a bar feeder is much easier, cheaper and less space consuming than retrofitting one of our machining centres with robotic machine tending.

“So I decided that investment in autonomous turning and milling of components in one hit was the way forward and it is proving to be the right choice.

“We will now progress to turning on the L32 without the guide bush for all but the longest shaft-type components, which are rare orders for us at the moment as we are not known as a sliding-head shop, but of course we are now in a position to fulfil that work.

“The expectation is that we will also use the Cincom for machining purely prismatic parts with no turning at all apart from parting-off, which will go some way to automating production of some of our milled parts as well.”

Now a vast range of legacy threaded components, from the biggest Whitworth to the smallest BA (British Association) size and everything in between, is manufactured by Historic Threads and sold on its website

Now a vast range of legacy threaded components, from the biggest Whitworth to the smallest BA (British Association) size and everything in between, is manufactured by Historic Threads and sold on its website  Shortly after the machine was delivered, Mr Swaffield received DWS Engineering’s biggest ever single order for the supply of brass, aluminium and stainless steel parts from 10 to 20 mm in diameter for use in the assembly of make-up brushes and pencils.

Shortly after the machine was delivered, Mr Swaffield received DWS Engineering’s biggest ever single order for the supply of brass, aluminium and stainless steel parts from 10 to 20 mm in diameter for use in the assembly of make-up brushes and pencils.

S Lilley & Son Ltd’s transition from cam-type to CNC lathes started in 2008, somewhat later than in many manufacturing companies for three reasons. First, as tolerances on its electrical products are not particularly tight, their production is relatively unaffected by the age of a machine tool; second, the fittings are frequently needed in large volumes commensurate with single-spindle cam auto operation; and third, the company was fortunate to employ a highly skilled cam auto setter-operator who retired as recently as 2019. That was when the penultimate cam-controlled machine was sold, the single remaining auto being devoted to a particular long-running job.

S Lilley & Son Ltd’s transition from cam-type to CNC lathes started in 2008, somewhat later than in many manufacturing companies for three reasons. First, as tolerances on its electrical products are not particularly tight, their production is relatively unaffected by the age of a machine tool; second, the fittings are frequently needed in large volumes commensurate with single-spindle cam auto operation; and third, the company was fortunate to employ a highly skilled cam auto setter-operator who retired as recently as 2019. That was when the penultimate cam-controlled machine was sold, the single remaining auto being devoted to a particular long-running job. In January 2022 a fourth Cincom arrived, an

In January 2022 a fourth Cincom arrived, an

“Admittedly part of the rising sales figures is down to an increase in material costs but the underlying growth is undeniable, due in part I believe to the trend towards re-shoring.

“Admittedly part of the rising sales figures is down to an increase in material costs but the underlying growth is undeniable, due in part I believe to the trend towards re-shoring. Notable also regarding the fixed-head lathes is their speed of production, despite their large size. Occasionally, when the sliding-head lathes are particularly busy, a production run is transferred to a fixed-head lathe with very little increase in cycle time. One component machined from 20 mm hexagonal bar, for example, takes 28 seconds to produce on a sliding-head lathe with gang tooling and only 32 seconds using a 65 mm capacity Miyano with turret tooling.

Notable also regarding the fixed-head lathes is their speed of production, despite their large size. Occasionally, when the sliding-head lathes are particularly busy, a production run is transferred to a fixed-head lathe with very little increase in cycle time. One component machined from 20 mm hexagonal bar, for example, takes 28 seconds to produce on a sliding-head lathe with gang tooling and only 32 seconds using a 65 mm capacity Miyano with turret tooling.

The lathe proved to be easy to operate by simply reading the manual. Word soon spread throughout Wiltshire and further afield that the capacity was available and CIRC started receiving more enquiries for complex turned parts. Most were fulfilled, although some had to be turned down as the machine does not have a full C-axis on the main and sub spindles, only 15-degree indexing.

The lathe proved to be easy to operate by simply reading the manual. Word soon spread throughout Wiltshire and further afield that the capacity was available and CIRC started receiving more enquiries for complex turned parts. Most were fulfilled, although some had to be turned down as the machine does not have a full C-axis on the main and sub spindles, only 15-degree indexing. There are generally two impediments to lights-out production, according to Mr Pearce, namely component dimensions drifting out of tolerance and swarf build-up in the machining area requiring operator attendance to remove it. The latest lathe avoids both problems and therefore frequently runs unmanned overnight. The first issue is addressed by the presence of thermal compensation sensors around the machine and the second by Citizen’s

There are generally two impediments to lights-out production, according to Mr Pearce, namely component dimensions drifting out of tolerance and swarf build-up in the machining area requiring operator attendance to remove it. The latest lathe avoids both problems and therefore frequently runs unmanned overnight. The first issue is addressed by the presence of thermal compensation sensors around the machine and the second by Citizen’s

A notable technological advance from Citizen since DP Engineering purchased the earlier Cincoms was the introduction five years ago of its proprietary

A notable technological advance from Citizen since DP Engineering purchased the earlier Cincoms was the introduction five years ago of its proprietary  Another attribute of the latest three Cincom lathes that increases their versatility, apart from the extended periods of spindle uptime and unmanned running made possible by the LFV chip breaking software, is the ability to turn-mill shorter components in fixed-head mode without the guide bush, which can be removed and replaced within half an hour.

Another attribute of the latest three Cincom lathes that increases their versatility, apart from the extended periods of spindle uptime and unmanned running made possible by the LFV chip breaking software, is the ability to turn-mill shorter components in fixed-head mode without the guide bush, which can be removed and replaced within half an hour.

“It is programmable via G-codes to start and stop during any program, breaking what would normally be stringy swarf into smaller chips that cannot wrap around the tool or component and damage them.”

“It is programmable via G-codes to start and stop during any program, breaking what would normally be stringy swarf into smaller chips that cannot wrap around the tool or component and damage them.” It is noteworthy that, as is the case on more and more Cincoms and on some Miyano lathes, the most recent L20-VIIILFV delivered to Bishops Stortford has the chip-breaking functionality on both the main and sub spindle, whereas on earlier models it is applied to the main spindle only. The latest machine at Stellar was purchased for manufacturing ventilator parts for the NHS. Funding through Citizen UK Finance and a six-month payment holiday smoothed the acquisition process at a difficult time.

It is noteworthy that, as is the case on more and more Cincoms and on some Miyano lathes, the most recent L20-VIIILFV delivered to Bishops Stortford has the chip-breaking functionality on both the main and sub spindle, whereas on earlier models it is applied to the main spindle only. The latest machine at Stellar was purchased for manufacturing ventilator parts for the NHS. Funding through Citizen UK Finance and a six-month payment holiday smoothed the acquisition process at a difficult time.

That level of accuracy is achieved reliably, even when running lights-out, partly because the lathe incorporates

That level of accuracy is achieved reliably, even when running lights-out, partly because the lathe incorporates  “Normally, to achieve cost-effective levels of productivity when mill-turning components from smaller diameter bar, you would not put that work on a lathe with double the bar capacity or more, as you would expect it to be slower.

“Normally, to achieve cost-effective levels of productivity when mill-turning components from smaller diameter bar, you would not put that work on a lathe with double the bar capacity or more, as you would expect it to be slower.

“Even smaller quantities are economical to produce, partly because we have adopted a policy of standardising on one size of stock on each of the Cincoms, so we do not have to waste time changing over bar sets.

“Even smaller quantities are economical to produce, partly because we have adopted a policy of standardising on one size of stock on each of the Cincoms, so we do not have to waste time changing over bar sets. To alleviate it, the LFV function can be switched on and off via G-codes in the part program, enabling optimal use of the feature during different parts of a cycle. It is, however, not a pecking macro in the CNC program itself. As one operator looks after the four sliding-head lathes, LFV is helpful in minimising periodic attendance at the machines to disentangle clogged swarf. It is notable that the 8-axis L32 has LFV on both the main and counter spindles, allowing the oscillations that produce the chip breaking action to assist in the production of both front- and reverse-end turned, milled and drilled features.

To alleviate it, the LFV function can be switched on and off via G-codes in the part program, enabling optimal use of the feature during different parts of a cycle. It is, however, not a pecking macro in the CNC program itself. As one operator looks after the four sliding-head lathes, LFV is helpful in minimising periodic attendance at the machines to disentangle clogged swarf. It is notable that the 8-axis L32 has LFV on both the main and counter spindles, allowing the oscillations that produce the chip breaking action to assist in the production of both front- and reverse-end turned, milled and drilled features.

The other lathes in the factory all have twin turrets and Owen had ordered a similar specification for the 80 mm model. Due to the cancellation of the MACH 2020 machine tool exhibition, however, which should have been held in Birmingham last April, Citizen Machinery had in stock a triple-turret ABX-64THY (80 max dia) 12-axis model with a Fanuc control system that it had intended to launch at the show. Owen was initially hesitant when offered the machine, having never used a lathe of that configuration before, but decided to buy it anyway as it was available immediately. It turned out to be a revelation.

The other lathes in the factory all have twin turrets and Owen had ordered a similar specification for the 80 mm model. Due to the cancellation of the MACH 2020 machine tool exhibition, however, which should have been held in Birmingham last April, Citizen Machinery had in stock a triple-turret ABX-64THY (80 max dia) 12-axis model with a Fanuc control system that it had intended to launch at the show. Owen was initially hesitant when offered the machine, having never used a lathe of that configuration before, but decided to buy it anyway as it was available immediately. It turned out to be a revelation. Another example of where the 80 mm bar machine has introduced benefits is when machining one of the few Andair components the pilot actually sees, a fuel selector fascia plate that requires a very high surface finish, which is achieved on the aluminium part using a diamond tipped tool. The plate is also engraved to indicate which tank has been selected. Previously, after turning it from a billet, a second operation was required on a machining centre to mill material from the reverse and to drill four holes.

Another example of where the 80 mm bar machine has introduced benefits is when machining one of the few Andair components the pilot actually sees, a fuel selector fascia plate that requires a very high surface finish, which is achieved on the aluminium part using a diamond tipped tool. The plate is also engraved to indicate which tank has been selected. Previously, after turning it from a billet, a second operation was required on a machining centre to mill material from the reverse and to drill four holes.