Citizen Machinery will reaffirm its position not only as the leading supplier of bar-fed lathes into the British and Irish markets, but also as a pioneer in implementing attendant technologies that take that pre-eminence to the next level in terms of innovative production. The company’s patented LFV (low frequency vibration) chip breaking software, its wealth of options for automating production, and integral laser cutting in its Cincom sliding-head lathes are three examples.

The focus will be on Citizen’s proprietary LFV operating system software that ensures efficient chip breaking and every sliding-head mill-turn centre on the stand will have this functionality (Hall 20, stand 361). 2024 marks the sixth anniversary of the technology’s launch.

It has had a transformative effect on sales of Cincom sliders around the world, and also of selected models within Citizen’s fixed-head Miyano turning centre range, owing to the superiority of chip breaking over that achievable with conventional pecking macros and dwells. That is especially the case when machining stainless steel, aluminium, copper, various exotic materials and plastics. There is also a noticeable improvement in tool life and surface finish due to the avoidance of recutting of chips.

Problems arising from stringy swarf entangling around the workpiece and tool are prevented by vibrating the X and Z servo axes in the direction of cutting in synchrony with rotation of the spindle. The function, which has three alternative modes, may be used with static and driven tools. It is especially helpful in generating manageable chip sizes when grooving, drilling deep, small-diameter holes, and internal and external thread cutting.

Sliding-head lathe tailored to medical component production

Visitors to the Citizen Machinery UK stand will learn that the configuration of the 12 mm bar capacity Cincom L12-X ideally suits it to the production of dental abutments and implants, as well as medical industry parts in general. Multiple rear-facing endworking tool positions including driven stations are provided, as well as a Y2-axis to the X2 and Z2 movements on the counter spindle to match the three degrees of freedom on the main spindle.

A modular tooling system has been adopted for the gang and back tool posts and an extensive variety of tooling layouts is possible, which includes the ability to drill angled holes. The maximum number of tools that can be deployed is 38. Unlike on other Cincom L12 models, a built-in 12,000 rpm motor drives the counter spindle, reducing acc/dec times for higher productivity. Rapid traverse in all axes of 35 m/min contributes further to minimising idle times.

32 mm capacity sliding-head lathes

Two Cincom lathes on the stand will have 32 mm bar capacity, including the L32-VIII, which accepts 38 mm stock if the guide bush is removed. It is one of four machines with exclusively gang toolposts in a modular range that allows a user to select a precise specification to suit the intended applications, while retaining the option of adding extra functionality later. The version on show will be a 7-axis model with up to 30 tools, said to have an excellent cost-performance ratio.

The other model is Citizen’s flagship sliding-headstock lathe, the 15-axis Cincom M32-VIII, now in its fifth design iteration. A 10-station turret, which runs on hardened box ways, incorporates a tooling system employing a single, heavy duty, 2.2 kW drive to power the live cutters. The gang tool post has been equipped with live tools powered by a 2.2 kW motor, as well as a programmable, 9,000 rpm B-axis to enable simultaneous machining in five CNC axes, while the back tool post with Y-axis has adjustable-angle tooling. Three tools may be in cut at the same time, supported by the Mitsubishi M850W control with 15-inch touch-screen HMI, shortening cycle times and raising productivity.

The lathe’s ecological credentials, as with other Citizen machines, are impeccable. The M32 is an environmentally friendly product that has undergone stringent assessment by the manufacturer. The use of easily recyclable materials and avoidance of hazardous substances are combined with Eco Function hybrid technology that automatically saves energy through the intelligent use of power during non-cutting periods.

Triple Y-axis turret lathe

One of the larger bar capacity CNC lathes in the Citizen Machinery product portfolio is the 12-axis Miyano ABX-64THY, a fixed-head model with twin-opposed C-axis spindles and three turrets moving over box ways for maximum rigidity. The turning centre is ideal for continuous, automated, unattended production of components from bar up to 64 mm in diameter. Maximum component diameter when chucking is 165 mm. Rapid traverse rates are fast at up to 30 m/min in Z, promoting short non-cutting times.

The three turrets, which have 80 mm of Y-axis movement, can all be in cut simultaneously to achieve very high levels of productivity. Two turrets are positioned above the spindle centreline and are dedicated to working at the 15 kW / 2,750 rpm main spindle and 7.5 kW / 5,000 rpm counter spindle respectively. The other turret is located below and has unrestricted travel to operate at either spindle to provide flexibility for balancing front and reverse end machining operations, or to deploy a tailstock centre to support shaft-type components being machined in either spindle.

Temperature variations around the machine are constantly measured by sensors and fed back to the Fanuc Series 30i-B control, which incorporates software to compensate for thermal movement by adjusting the relevant axis positions. In this way, displacement of the turret from the main spindle in the X-axis, for example, is reduced from 30 down to 10 microns. An in-machine tool setter, parts catcher and conveyor, and a variety of different swarf conveyors to suit the type of chip are all available.

Double Y-axis fixed-head lathe with Fanuc control and LFV

The first fixed-head lathe in Citizen Machinery’s Miyano range to have the company’s patented LFV chip breaking software in a Fanuc control system was the 42 mm bar capacity ANX-42SYY. It features 10 CNC axes including a ± 35 mm Y-axis on both the upper and lower turrets in addition to X- and Z-axis movements, enabling the production of complex components to tight geometrical tolerances.

The compact mill-turn centre is ideal for OEMs and subcontractors keen to leverage the quality and productivity of a Miyano lathe and at the same time standardise on Fanuc controls on their shop floor for the sake of operator familiarity and compatibility with other machines. The 15-inch XGA (extended graphics array) touch panel Fanuc 31i control features a new Citizen HMI and incorporates the company’s multi-axis technology.

The 6.2-tonne machine occupies only 2,650 mm x 1,630 mm of space on a shop floor. Both main and sub spindle have a bar capacity of 42 mm diameter and are powered by 11 kW / 6,000 rpm built-in motors. The turrets have 12 live tool stations each rated at 6,000 rpm / 2.2 kW / 20 Nm. Rapid traverse rates are fast at up to 30 m/min, again with high productivity in mind. This has been achieved by adopting linear guides in all axes. Commonality of tool holders with Citizen’s popular BNA range of Miyano lathes leads to cost savings for existing users of the supplier’s equipment.

Turning and milling centre with two Y-axis turrets

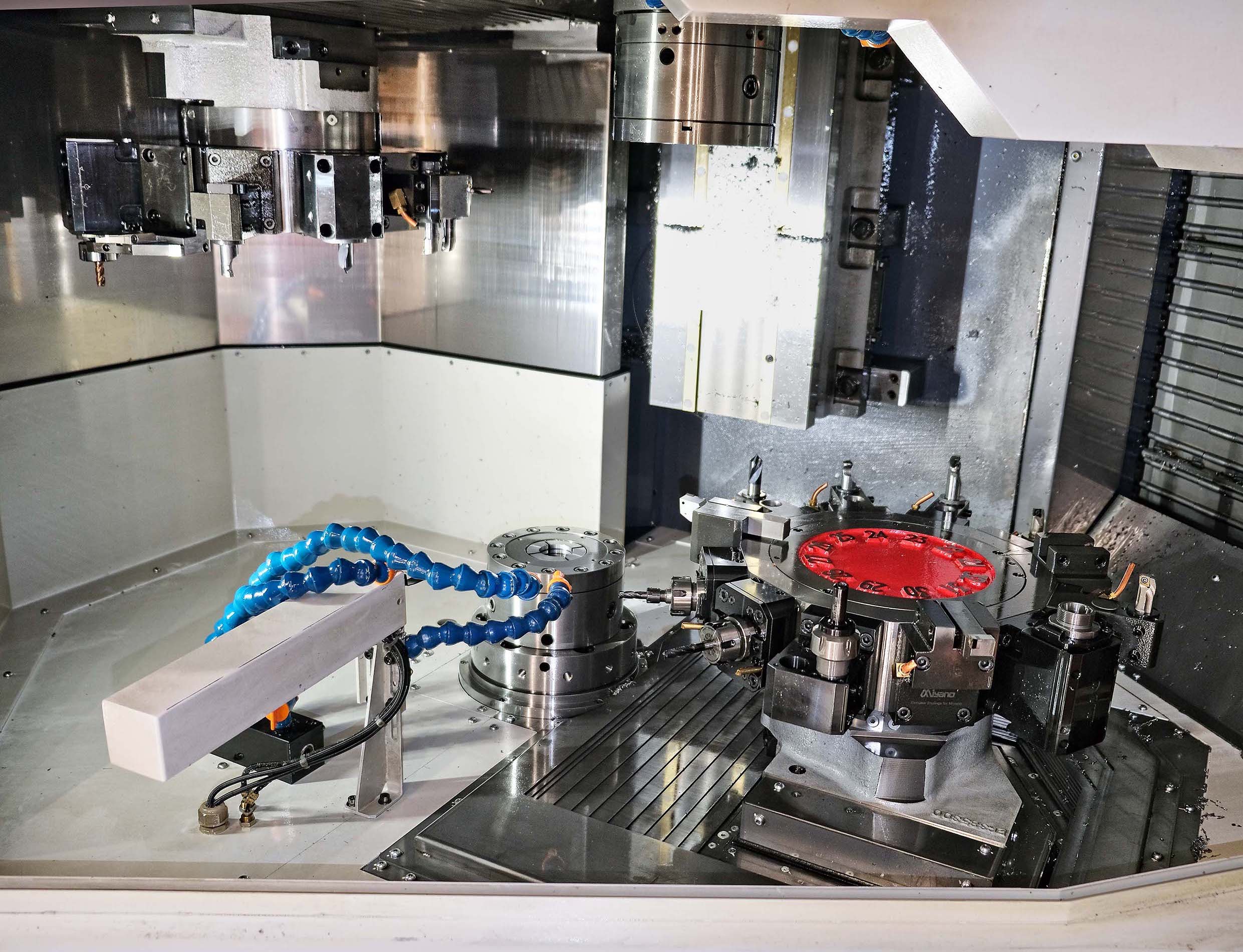

Complex components up to 65 mm in diameter may be turned and milled from bar in a new Miyano fixed-head lathe. The eight-tonne BNE-65MYY is equipped with two turrets having Y-axis travel in addition to X- and Z-axis movements. One turret is positioned above and the other below the centreline of the twin-opposed spindles and both tool carriers have 12 live stations. A C-axis on each spindle and movement of the sub spindle in X and Z bring the bar auto’s CNC axis tally to 10.

Complex components up to 65 mm in diameter may be turned and milled from bar in a new Miyano fixed-head lathe. The eight-tonne BNE-65MYY is equipped with two turrets having Y-axis travel in addition to X- and Z-axis movements. One turret is positioned above and the other below the centreline of the twin-opposed spindles and both tool carriers have 12 live stations. A C-axis on each spindle and movement of the sub spindle in X and Z bring the bar auto’s CNC axis tally to 10.

The two-axis movement of the sub spindle facilitates superimposed machining, whereby tooling on both faces of the top turret can simultaneously cut front-end features on the bar stock and reverse-end features on a parted-off component. With the lower turret also working at the main spindle performing pinch turning, milling or drilling, for example, or perhaps OD turning while axial drilling is in progress above, three tools are in cut at the same time.

Contributing to high productivity are fast rapid traverses up to 20 m/min, plus main and sub spindles with generous power ratings of 18.5 kW and 11 kW respectively. As both spindles rotate at up to 5,000 rpm, productive turning is maintained even when machining smaller diameter sections of a workpiece. Rotary tool specification is also impressive at 4 kW / 6,000 rpm.

Control is by the Mitsubishi M830W, which has a new HMI with a 15-inch touch-screen control for convenient operation, including on-screen selection of the turret tooling. Intelligence built into the control simplifies programming, especially of superimposed cycles by automatically synchronising those sections of the program.

Mill-turn centre prepared for automation

Building on the strengths of previous generations of Miyano fixed-head mill-turn centres, the BNA-42SY is one of Citizen Machinery’s latest additions to the range. The CNC lathe is the first BNA model to have a 12-station turret giving ± 35 mm of Y-axis movement, all tool positions now being live, and a new design that lends itself to easy automation. The latest FANUC 0i-TF Plus CNC system with 10.4-inch colour LCD screen controls the machine.

The rigid, 1,823 kg bed brings thermal control advantages. The base casting has been prepared with space at the right hand side for robotic load / unload equipment. If a user intends to take advantage of automation, the machine can be supplied with a swarf conveyor that exits to the rear as an option.

The automation may be employed solely for unloading components that have been mill-turned from bar stock up to 42 mm diameter, either directly from a spindle or via a parts catcher and conveyor. Alternatively, or in addition, it may load and unload billets or near net shape workpieces like castings or forgings up to 135 mm in diameter. A workpiece stocker is positioned at the right hand side of the machine to accommodate the finished components.

Mounting points have been included to provide an option to add an overhead gantry if only chucking is to be carried out, in which case a raw material stocker can be positioned to the left of the machine in place of the bar magazine. For complete flexibility in layout, top shutter and auto door options are offered.

Use of an inverter-controlled, hydraulic unit results in a large reduction in power drawn. Standby power consumption is just 0.661 kW, as servomotor readiness is automatically turned off when it is not needed, for example during program editing. Overall energy consumption can be visualised via a power monitor window on the control screen.

Improved production efficiency in a small footprint

The GN3200W is a twin-spindle, fixed-head lathe equipped with a high-speed loader for high productivity. The compact machine width is 33 percent narrower than previous Miyano models and the required floor space has been reduced by 27 percent, realising significant space saving. A wide choice of infeed/outfeed devices, single or double high speed gantry loaders, transfer and turnover units makes the machine an ideal choice to meet automation needs.

The concept when designing the machine was to prevent thermal displacement by transferring the heat generated by machining into the machine body. This is achieved by having a frame and bed with a thermally symmetrical design, backed up by a wing-type headstock and a separate coolant tank.

He contrasted this with the much longer and more expensive route that would have been needed with the other slider, for which a similar wizard was not available. First, it would have been necessary to purchase a sliding-head turning software licence for h2m’s seat of EdgeCAM, as well as a post processor for the lathe.

He contrasted this with the much longer and more expensive route that would have been needed with the other slider, for which a similar wizard was not available. First, it would have been necessary to purchase a sliding-head turning software licence for h2m’s seat of EdgeCAM, as well as a post processor for the lathe.

Complex components up to 65 mm in diameter may be turned and milled from bar in a new Miyano fixed-head lathe. The eight-tonne

Complex components up to 65 mm in diameter may be turned and milled from bar in a new Miyano fixed-head lathe. The eight-tonne

Programs are normally prepared offline with Esprit CADCAM and also using Citizen Machinery’s own

Programs are normally prepared offline with Esprit CADCAM and also using Citizen Machinery’s own