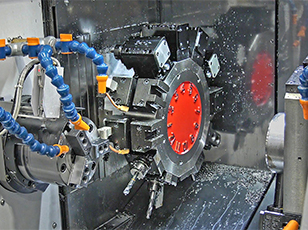

Featuring 2 spindles and 2 turrets, the main turret with Y axis function the BNJ-42SY6 / 51SY6 allows simultaneous and complex machining.

- Processing overlap control with main spindle processing combined with separate sub-spindle movement

- Eccentric collet enables complex machining of cranks and other eccentric processing

- It makes easy side milling through the Y-axis function of main turret, thus enables machining of large-diameter screws and/or uneven parts that was impossible to conduct by conventional machines

Subscribe to Citizen Machinery UK

Subscribe to Citizen Machinery UK